Introduction

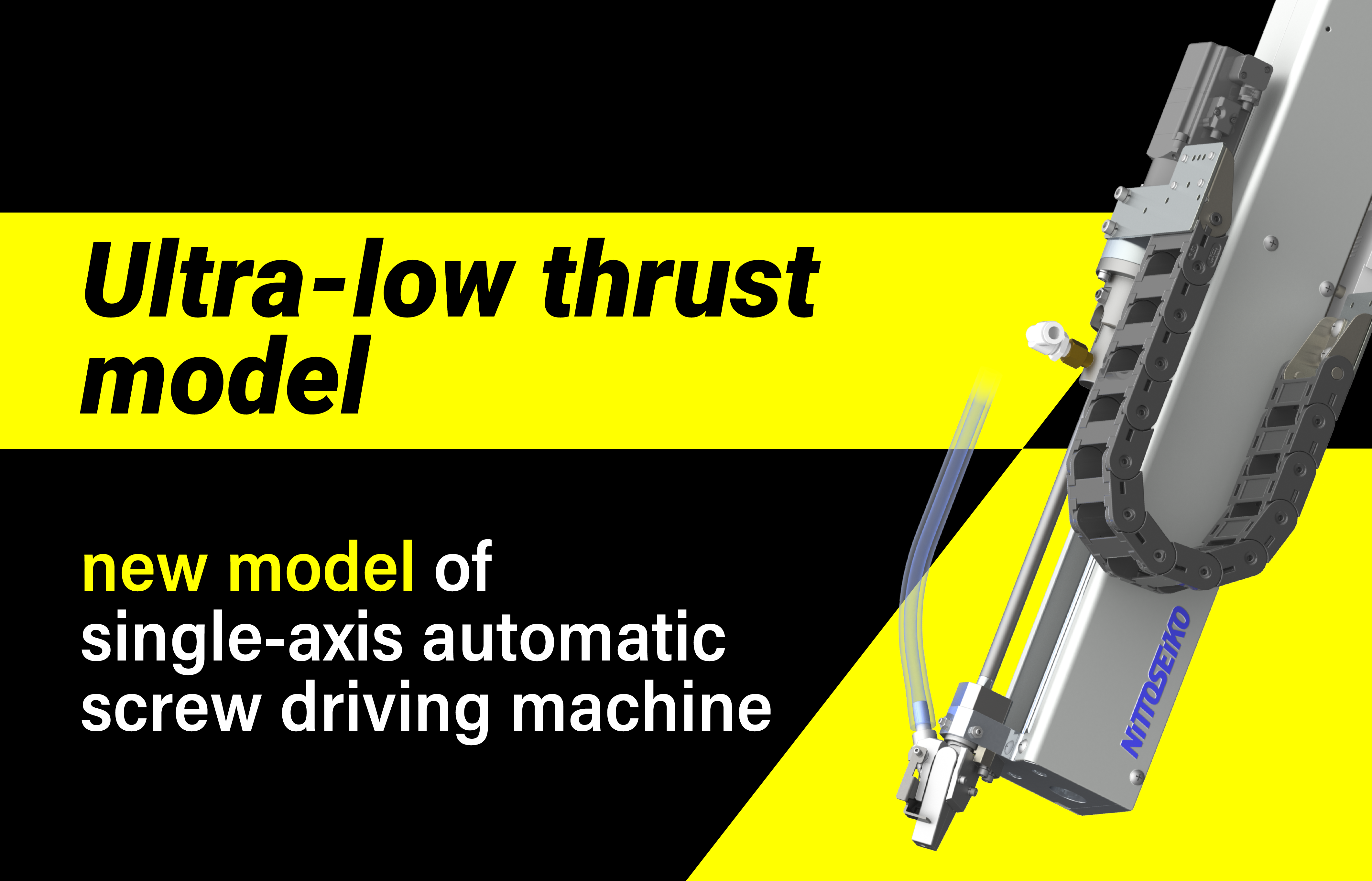

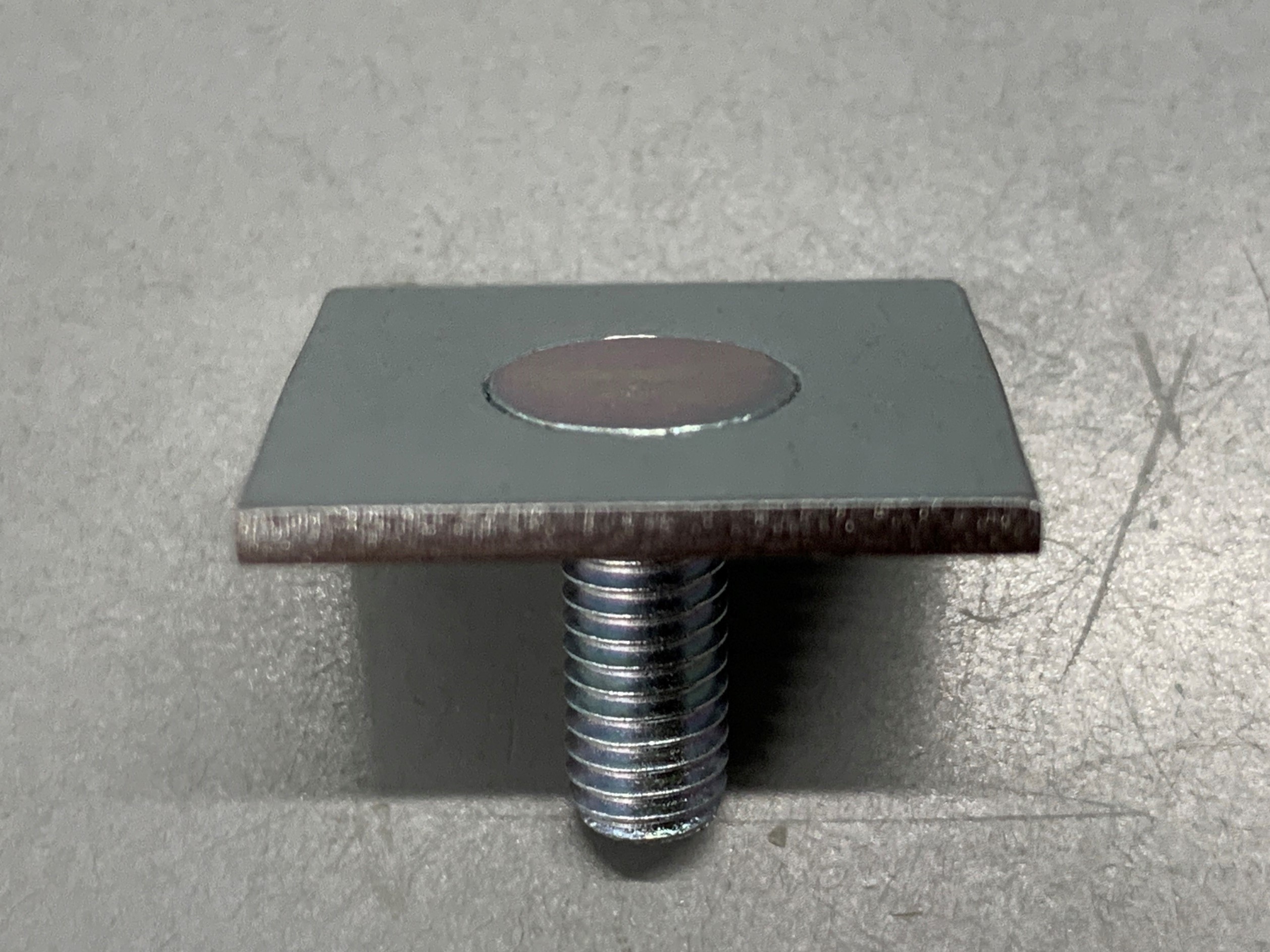

NITTOSEIKO CO., LTD. (Headquarters: 20, Umegahata, Ikura, Ayabe, Kyoto. President : Makoto Araga, TSE Prime, https://www.nittoseiko.co.jp/) has released the“JOISTUD-FH”. This is a clinching stud bolt with the embedded head that does not protrude from the fastening member after press-fitting. Orders will begin to be accepted from December 1, 2024. For this product, we have already applied for a patent.

Background of Development

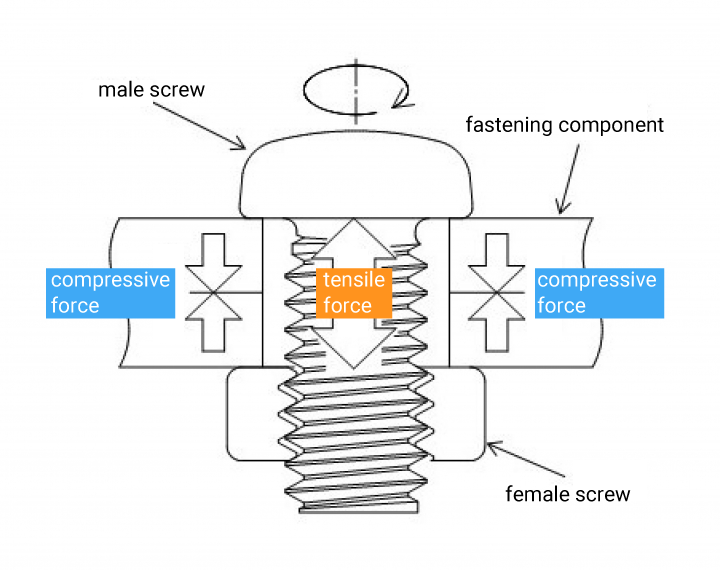

This clinching stud bolt, in which the head is press-fitted into a fastening member such as a steel plate to make it one piece, is used in many industries, especially in the automobile industry. As products become more advanced and the number of components increases, clinching stud bolts are required to be smaller and to save space due to the need to place components in a limited space. In addition, clinching stud bolts with low heads that are currently available on the market sometimes have problems with deformation or sinking of the head when fastened with high tightening torques or when subjected to external forces.

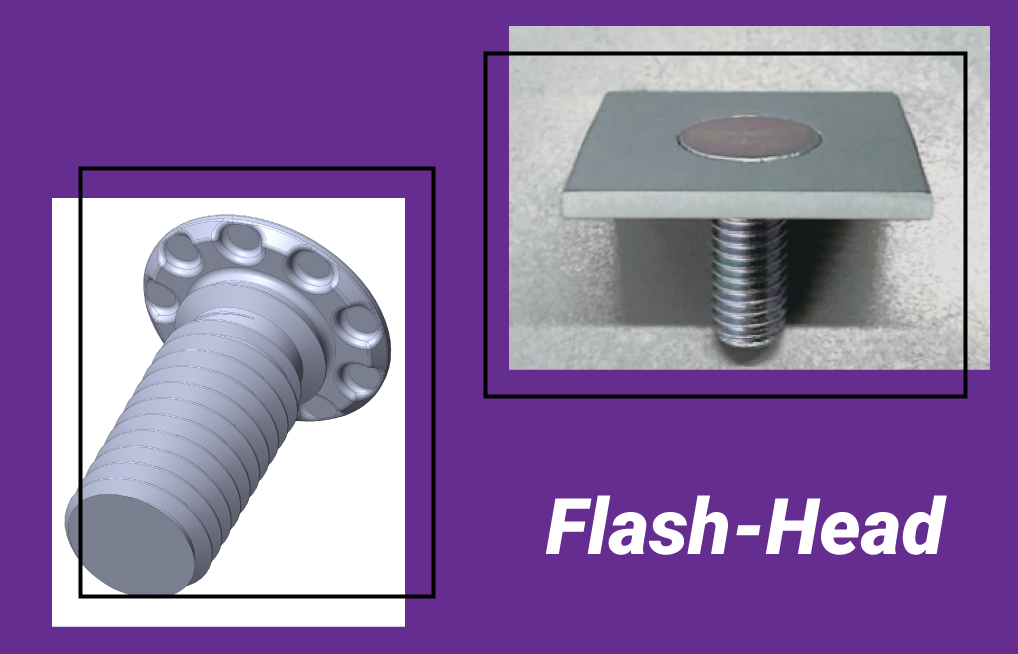

Against this background, we have developed the “JOISTUD-FH,” a clinching stud bolt with an embedded head that is safe when fastened and the head does not protrude after press-fitting into the fastening member. In addition, JOISTUD-FH reduces head sinkage caused by axial force during fastening, thereby providing strong support for customers' manufacturing activities.

Product description・feature

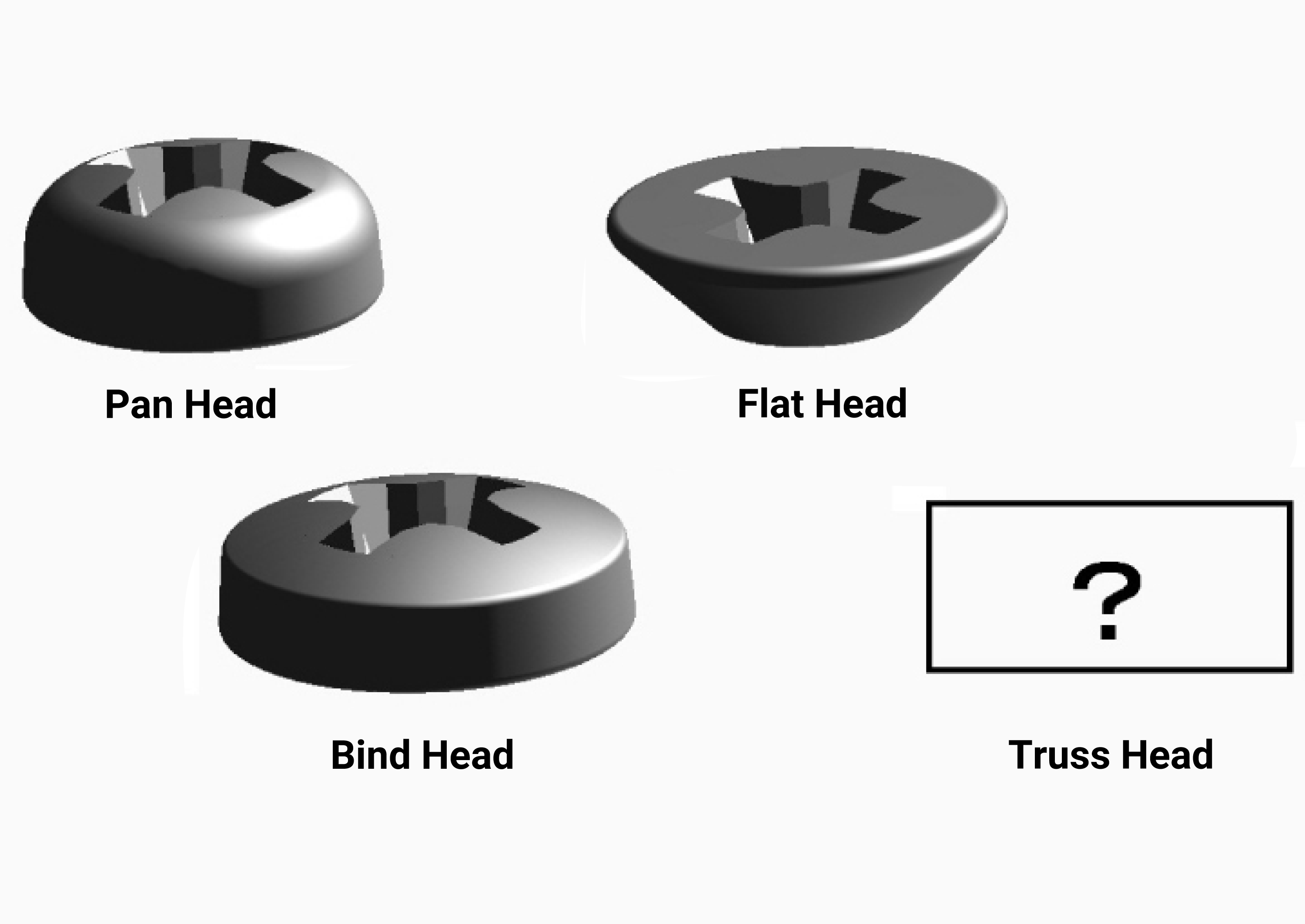

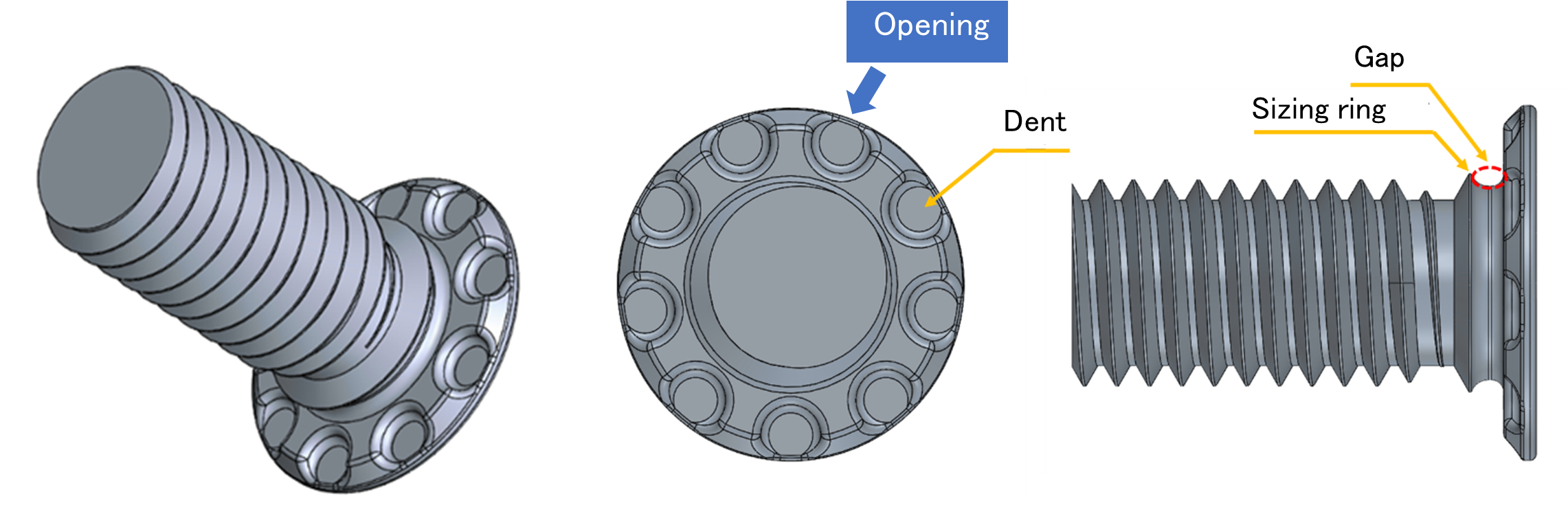

By reducing the thickness of the head to the minimum, “JOISTUD-FH” enables the entire circumference of the head to be press-fitted into the fastening member. On the other hand, nine circular dents (see below) in the bearing surface allow the fastening material to fill these dents during press-fitting to enable a high non-turnover effect. Just press-fit the JOISTUD-FH into the fastening member in the same way as conventional products, and it prevents protrusion of the head from the fastening member. In addition, the dent is partially open, which allows air to easily escape from here during press-fitting and assist the flow of fastening material into the dent.

Effect result

(1)Reduces head protrusion from fastening member significantly

The very thin head shape and dents allow the head to be press-fitted all the way into the fastening member. The head does not protrude from the fastening member after press fitting, thereby contributing to space saving.

|

|

|

|

|

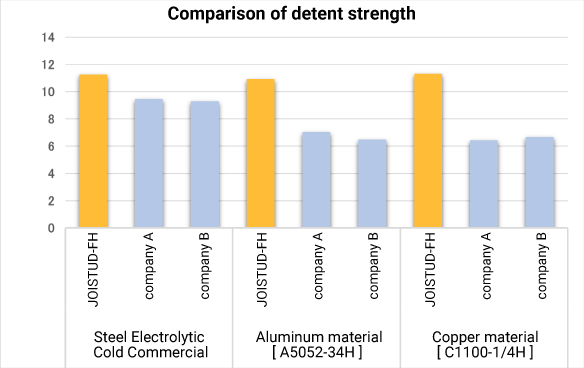

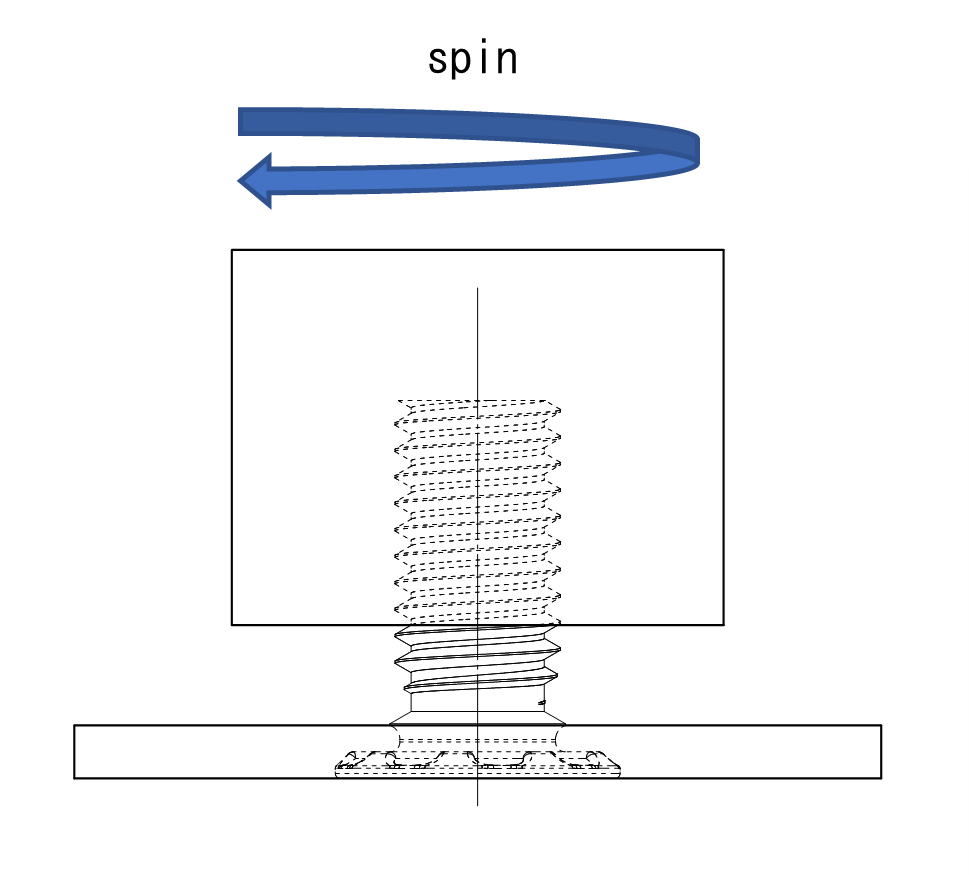

(2)Provides high detent strength

The recesses placed in the head bearing surface can be filled with fastening members, so that high non-turnover strength can be actualized.

|

|

|

|

Measuring method of detent strength |

※ According to our survey

※ Screw Size : M5

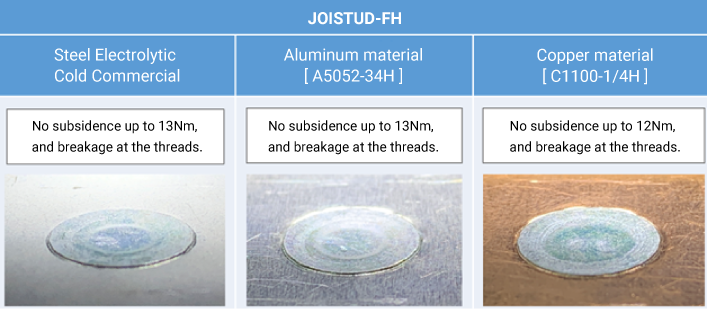

(3)Ensures high pullout strength

Compared to other companies' products, this screw has a larger head outer diameter, which reduces the risk of sinking during fastening and enables high-torque fastening.

※ According to our survey

※ Screw Size : M5

Product Specifications

Bolt size:Φ4、Φ5、Φ6

Applicable mating material:Steel, copper, aluminum, etc.

※Please feel free to contact us about other specifications.

■Future Developments

| Start Of orders | : | December1,2024 |

| Sales target | : | 1.5 million units per month |

| Target industry for the sale | : | Automotive parts industry, precision equipment and home appliance industry, etc. |