NITTOSEIKO CO., LTD. has added one new model of ultra-low thrust single-axis automatic screw driving machines, which will go on sale from February 14, 2025.

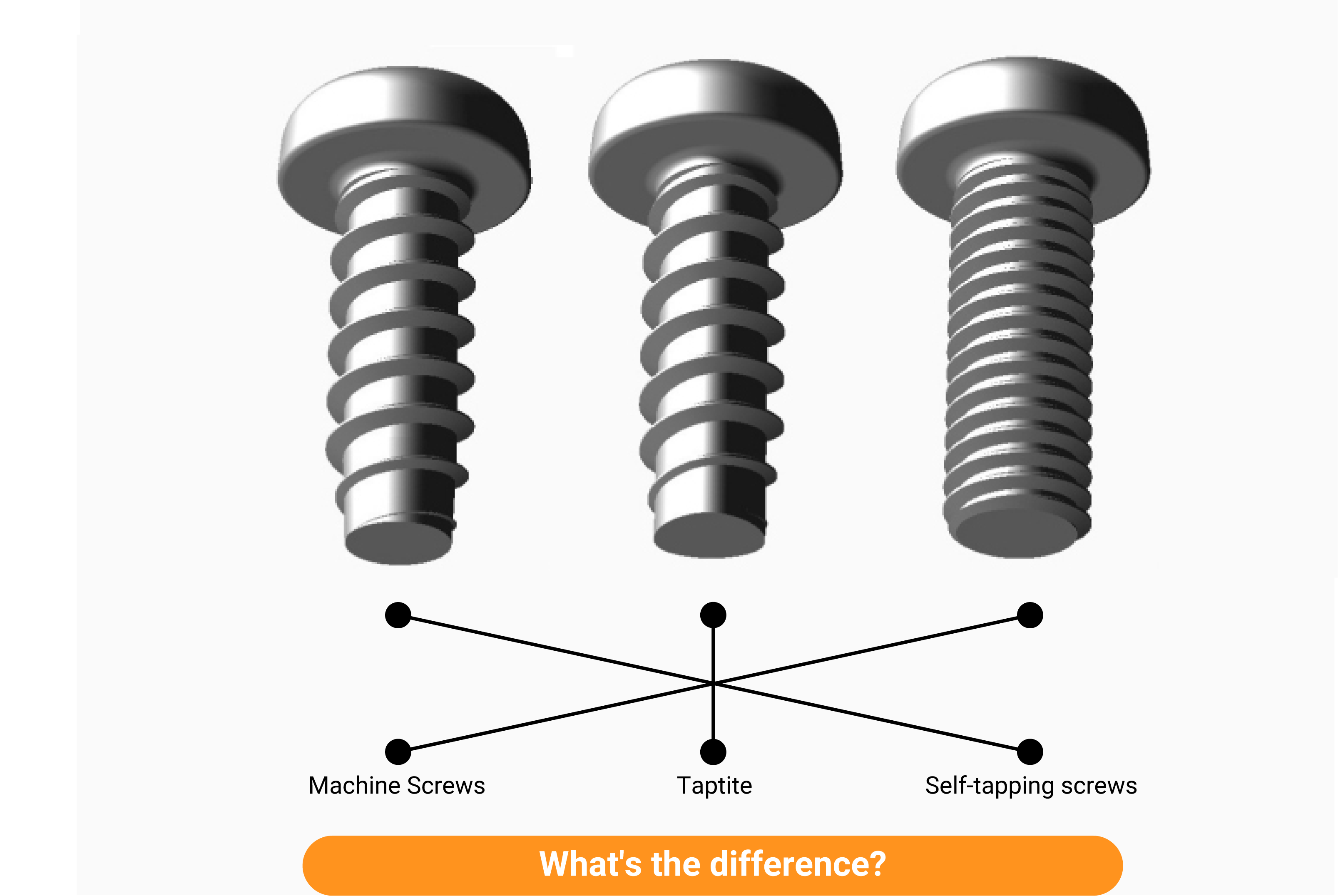

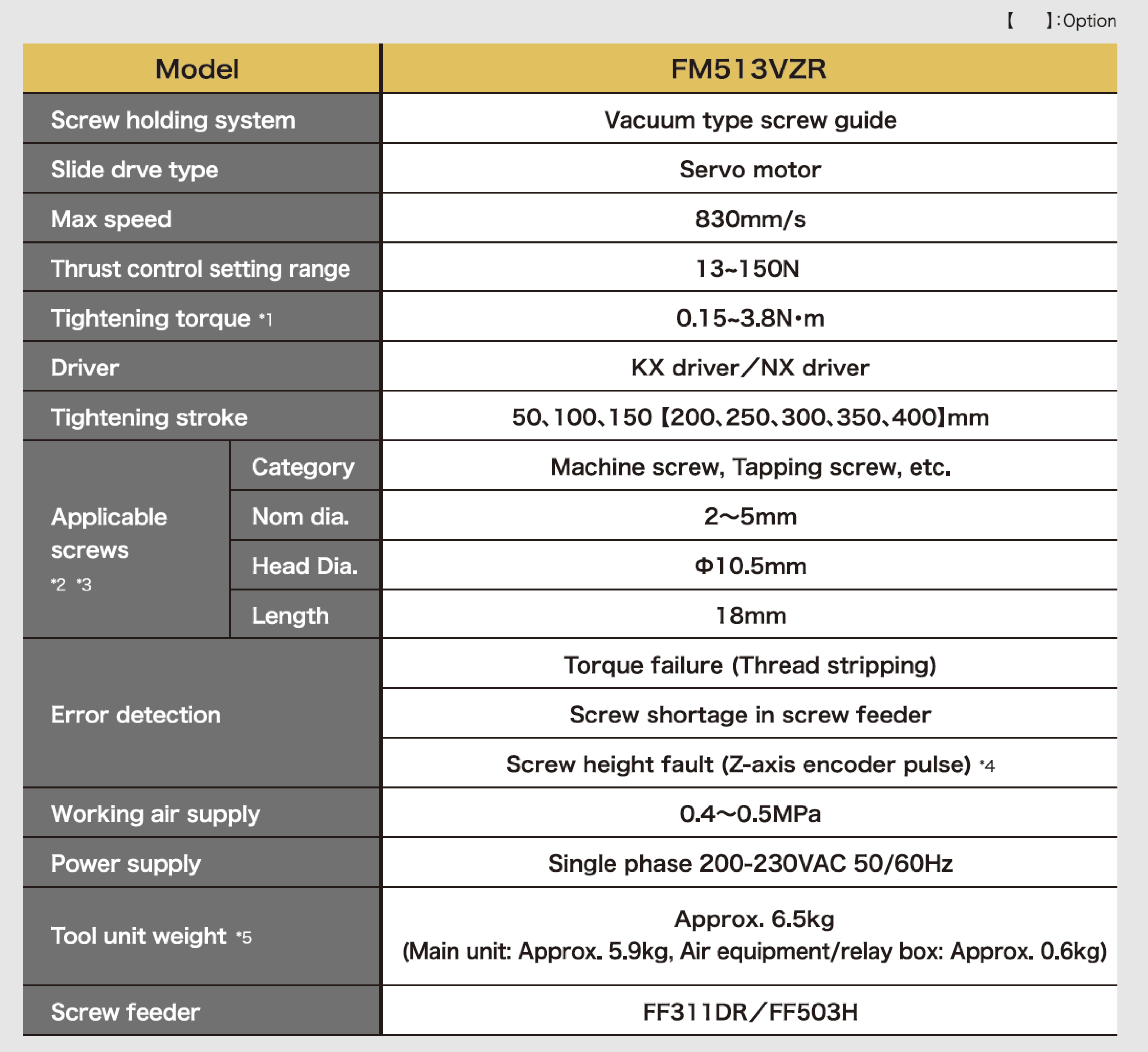

This product is a single-axis automatic screw driving machine that is compatible with small-diameter screws in the M2 to M5 class. By minimizing the thrust force during screw driving, it contributes to reducing the load on the workpiece and reducing screw driving defects such as seizing. In addition, it has achieved cycle time reduction by improving thrust force control.

Features

①Reducing the load on the work and reducing screw tightening defects

By offsetting the weight of the screwdriver bit lift mechanism against the pressing force (self-weight cancellation function), the thrust force during screw tightening is reduced by approximately 70% compared to conventional models, making it possible to tighten screws gently on the workpiece. This prevents seizing and diagonal tightening due to excessive thrust force. In addition, by reducing the thrust force when detecting screw height fault, the deflection of the workpiece is reduced, and the accuracy of the detection is improved. Furthermore, in situations where high thrust is required, such as when tightening screws for the final time, or depending on the characteristics of the workpiece and the tightening torque, it is also possible to tighten screws with the same thrust as conventional machines.

The thrust can be set in actual pressing force N (Newton), rather than the conventional percentage, making it possible to perform teaching work in a more intuitive way.

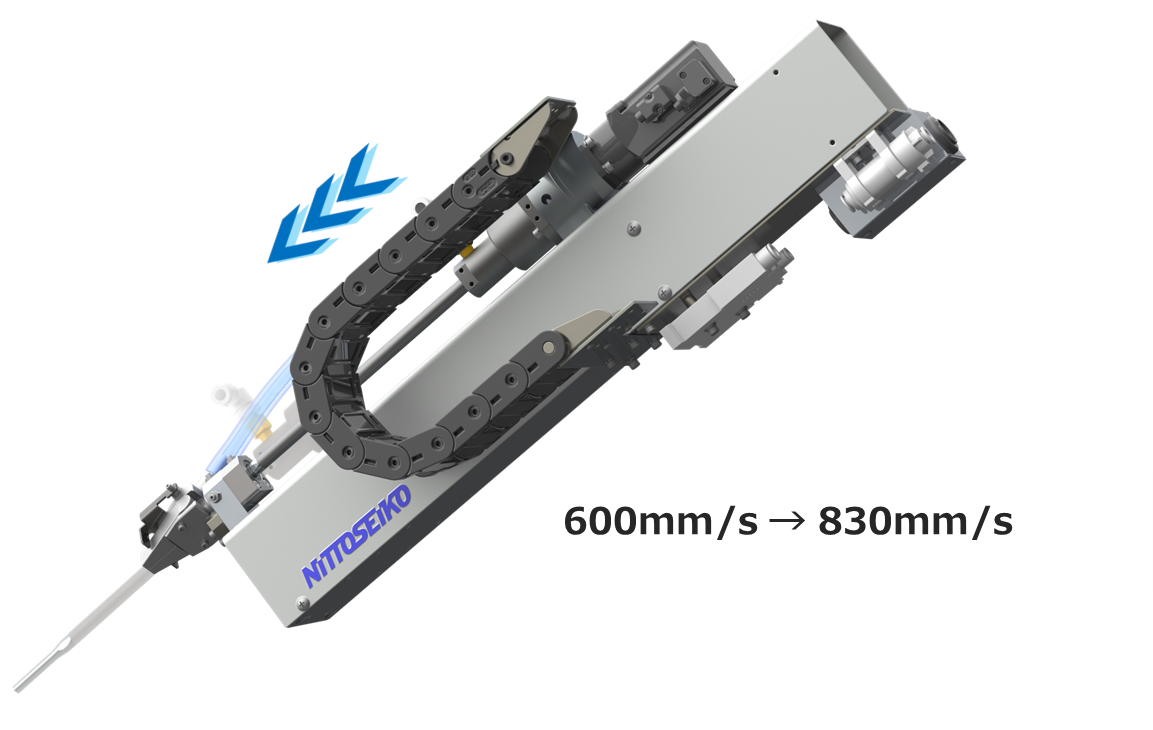

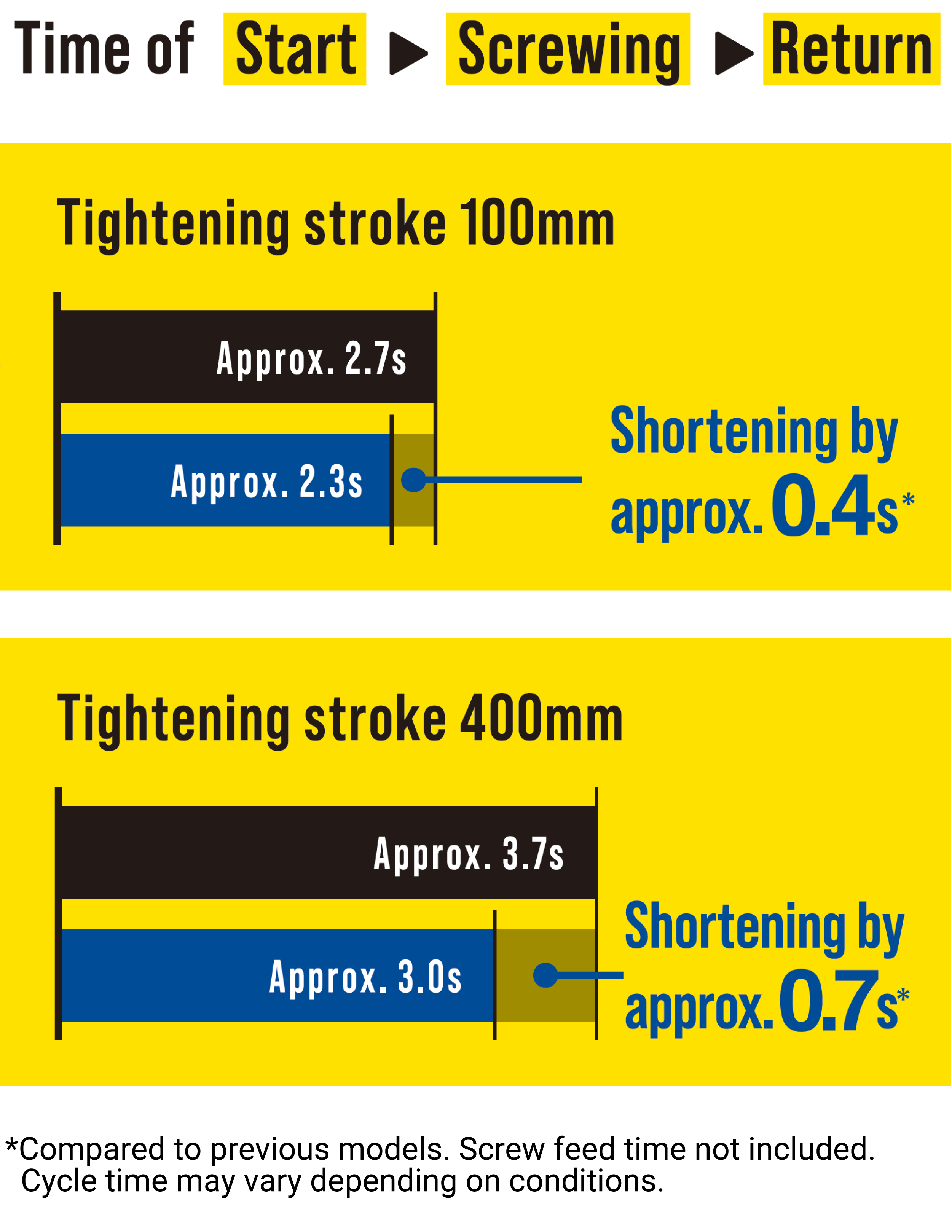

②Shortening cycle time through advanced thrust control

The advancement of the motion control system has enabled a significant reduction in cycle time. The maximum speed of the driver bit lift mechanism has been increased by approximately 40% compared to previous models, which is particularly effective in processes with long tightening strokes.

|

|

|

| Maximum speed Approx. 40%UP |

|

Reduce cycle time |

③More user-friendly

The cable carrier, which stores the wiring of the moving parts, is standard equipment. It protects the wiring, preventing wear and damage, and also improves maintainability.

The mounting dimensions of the screw tightening unit are compatible with the conventional FM513 series. It is also easy to replace the unit from a conventional model.

Examples of Usage

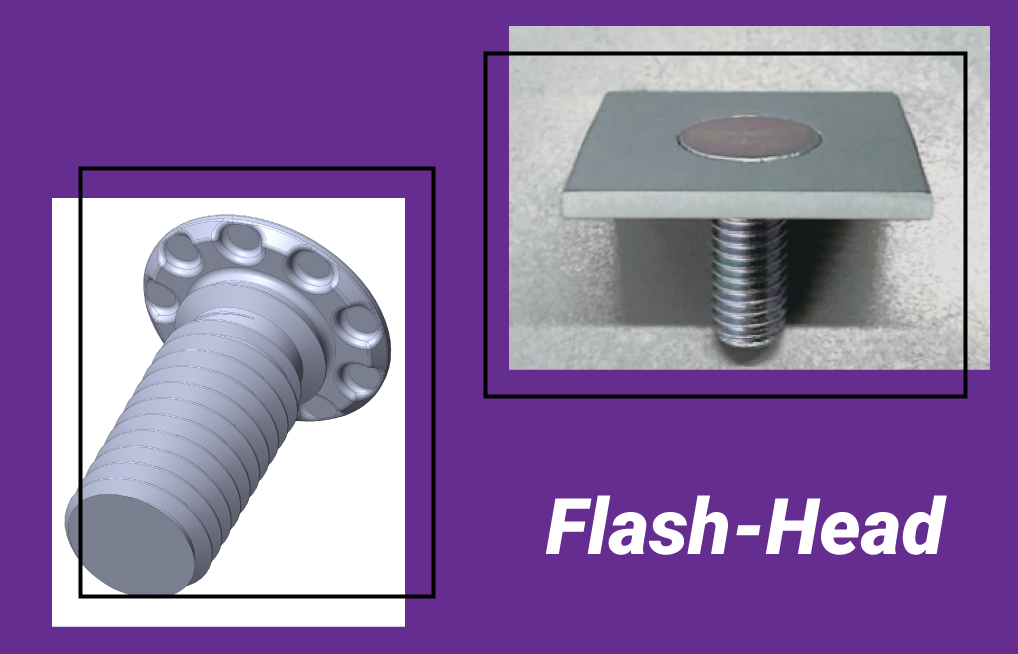

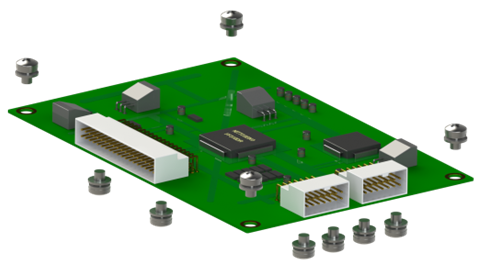

| ①Minimizing the load on the workpiece and reducing screw-tightening defects by minimizing the thrust force of the screw-tightening process 【Target products】ECU boards for in-vehicle use, LiDAR, etc. |

|

| ②Improving productivity by reducing cycle time 【Target products】Products that require a long tightening stroke, such as automobile headlights |

|

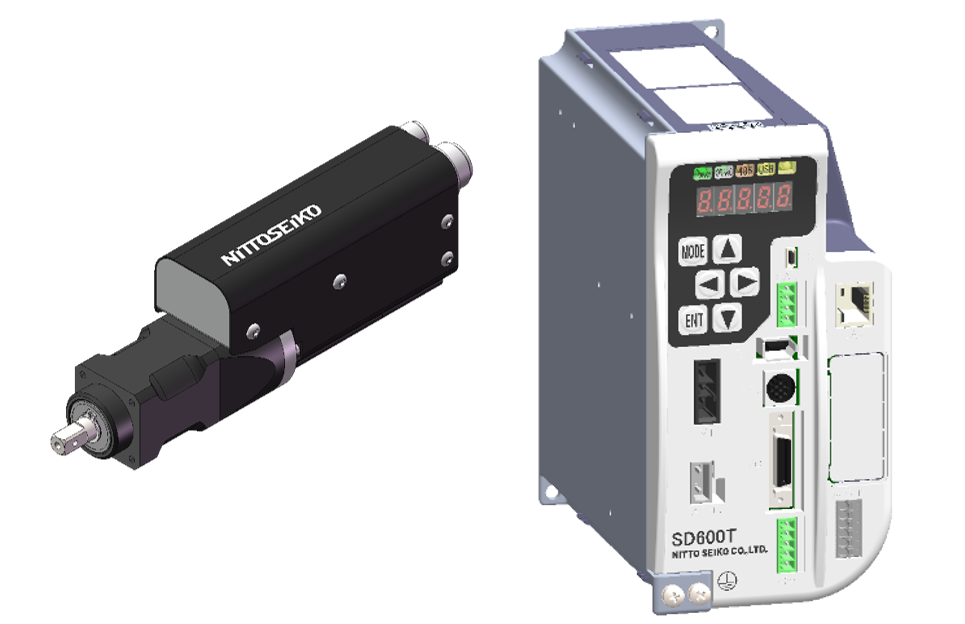

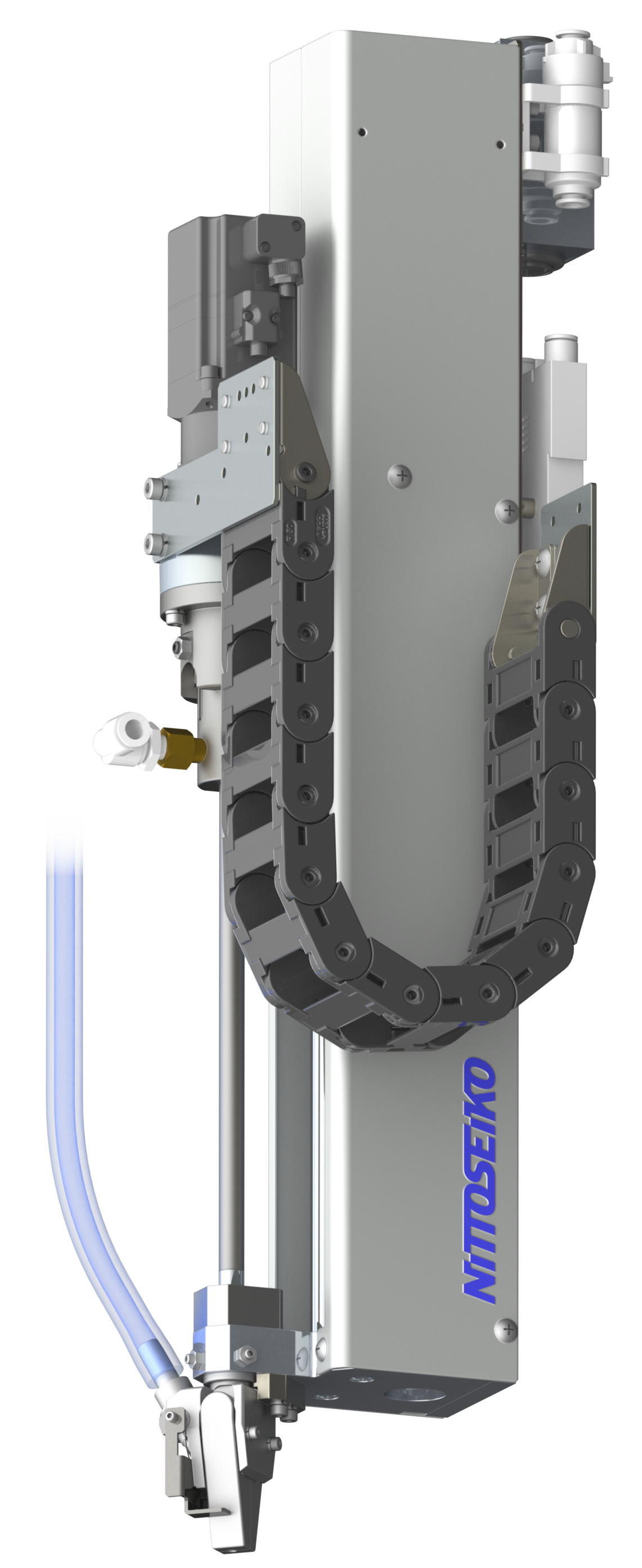

Product Appearance

|

|

|

|

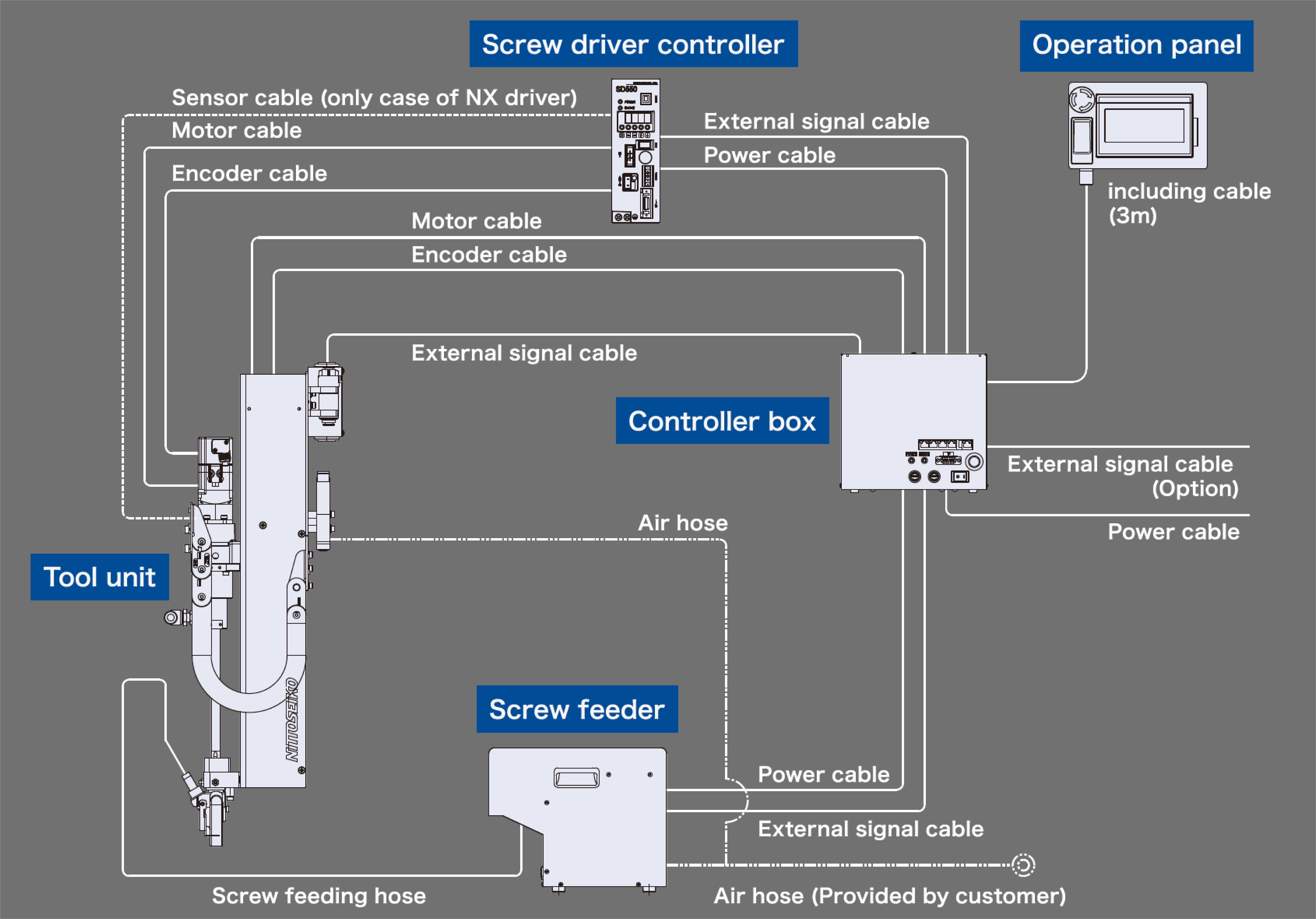

| Tool unit |

Controller box |

Screw driver controller |

Screw feeder |

Functions

Configurations

Future developement

For inquiries about product introductions, etc., please contact our sales representative.| Start of orders | : | February 14, 2025 |

| Sales target | : | 20 units per month |

| Main sales destinations | : | Automotive parts industry, home appliance industry, etc. |

| Configuration | : | ① Tool unit / FM513VZR ② Controller box / RC77R ③ Screw driver controller / SD550 ④ Screw feeder / FF503H ⑤ Cables and Connectors |

Leaflet