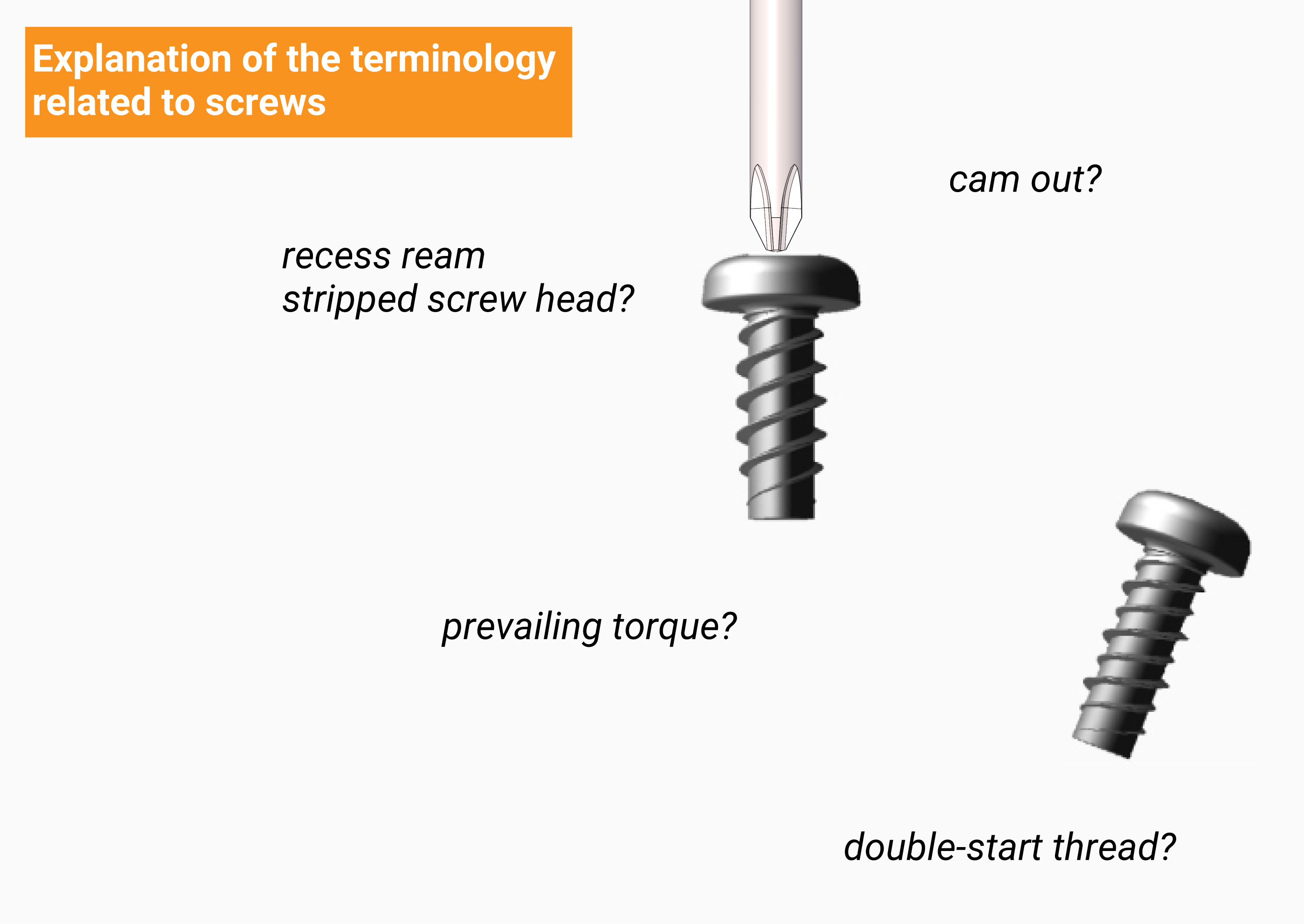

“Cam-out”? “Prevailing torque”? We will explain the terminology related to screws

|

thread forming screw |

Screws that can be screwed into unthreaded holes (pre-drilled holes) while allowing the screw itself to plastically form the female thread. |

|

self-tapping |

Threading a female thread into a mating material while allowing it to be plastically formed. |

|

mating material |

A member with a female screw or pre-drilled hole that is tightened with a screw to fasten the member. |

|

fastening component (clamped part) |

A component or part that is inserted between the head of a tapping screw and the mating material. |

|

pilot hole diameter |

Diameter of mating material preparation hole required for self-tapping |

|

thrust loading |

Thrusting force in the axial direction of a screw when fastening a screw |

|

cam out |

Insufficient force (thrust) to push the screw forward, causing the bit to lift off the crosspiece |

|

recess ream stripped screw head |

Cross-holes are crushed when tightening the cross-holes with a bit |

|

torsional strength |

Torque when twisting and breaking the screw itself |

|

tightening torque |

The torque required to screw a screw to obtain a given tightening force. |

|

driving torque |

The maximum value of torque required for a tapping screw to form a female thread in a mating material's downhole. |

|

(thread) stripping torque |

The maximum torque that can be applied to a thread or male screw molded into a mating material before it is broken. |

|

drive-to-strip torque ratio |

Ratio of starting torque to tightening breaking torque |

|

loosening torque |

Maximum torque required to loosen a screw after tightening to a specified tightening torque |

|

torque ratio of tightening loosening |

Ratio of Tightening Torque to loosening Torque |

|

axial tension |

The force applied in the axial direction of the screw, the strength of the fastening that compresses the fastening component. |

|

withstanding axial external force |

The maximum external force that a molded thread or male thread can withstand without breaking when an external force is applied in the axial direction from the opposite direction of the screwing in of a fastener fastened with a tapping screw. |

|

prevailing torque |

Frictional torque generated by interference between the threaded part of a male screw and female screw. |

|

taper |

An imperfectly threaded part where the threads are gradually reduced to improve screw threading performance at the tip of the screw. |

|

plain sheared end |

The tip of the male screw, without the tapered section, as it is after thread rolling |

|

lead angle |

The angle formed by the screw axis and the helix (screw thread line). |

|

pitch |

The distance between adjacent screw threads |

|

double-start thread |

A screw with two helix (screw threaded line) that advances two pitches per rotation. |

|

percentage of thread engagement |

The ratio of the height of the female screw thread (female screw thread height) to the height of the male screw thread (male screw thread height) |