About screw fastening

What is screw fastening?

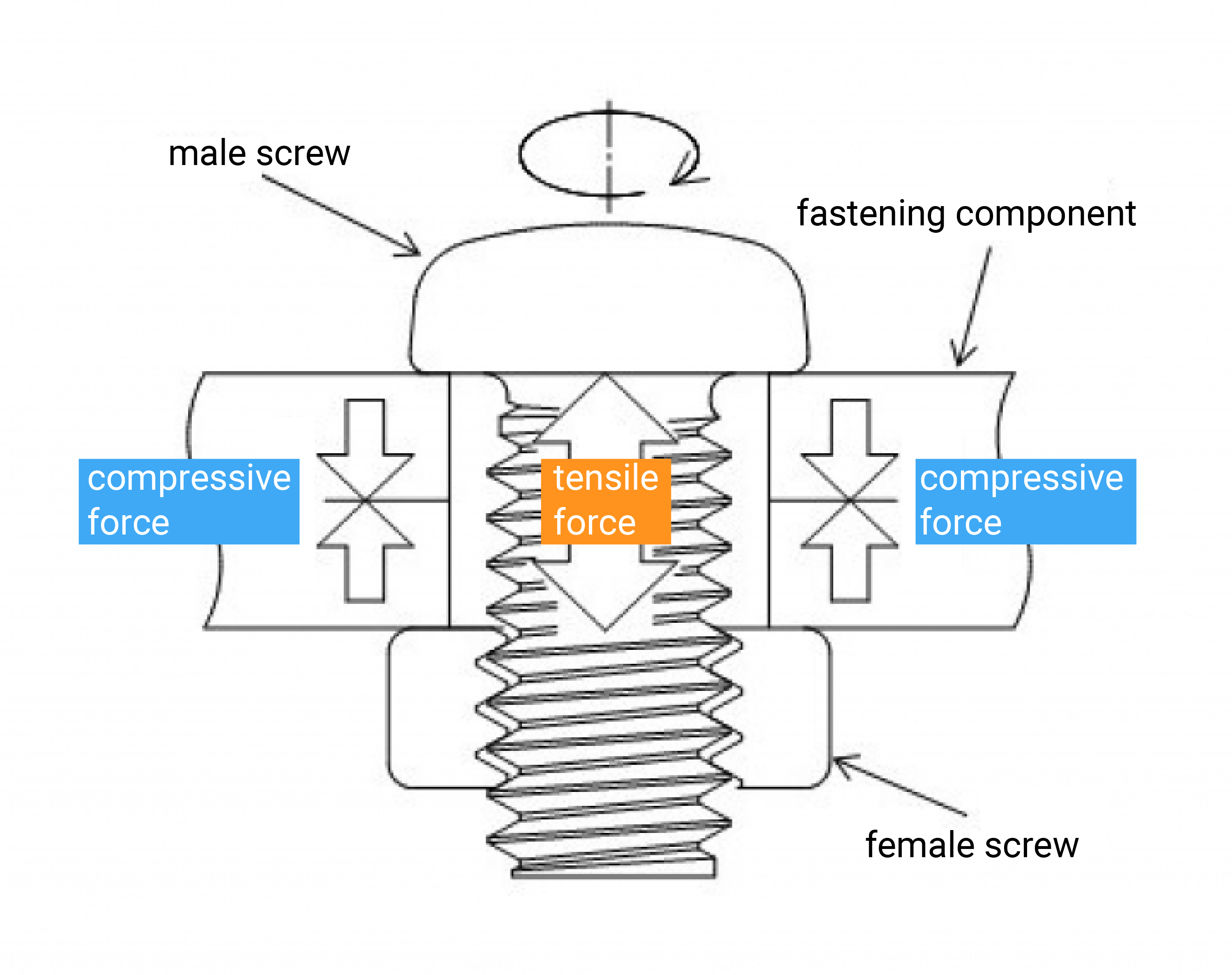

Screw fastening is the process of joining two or more components together using screw parts. When a screw is rotated to fasten two or more components together, the fastening component is subjected to compressive force (the force of being squeezed), and the screw is subjected to tensile force (the force of being pushed back by the fastening component). This force, combined with the frictional resistance of the screw threads and the screw-fastening surface of the male and female screws, results in a strong fastening. It is a necessary condition that the screw parts must not loosen during the period of use.

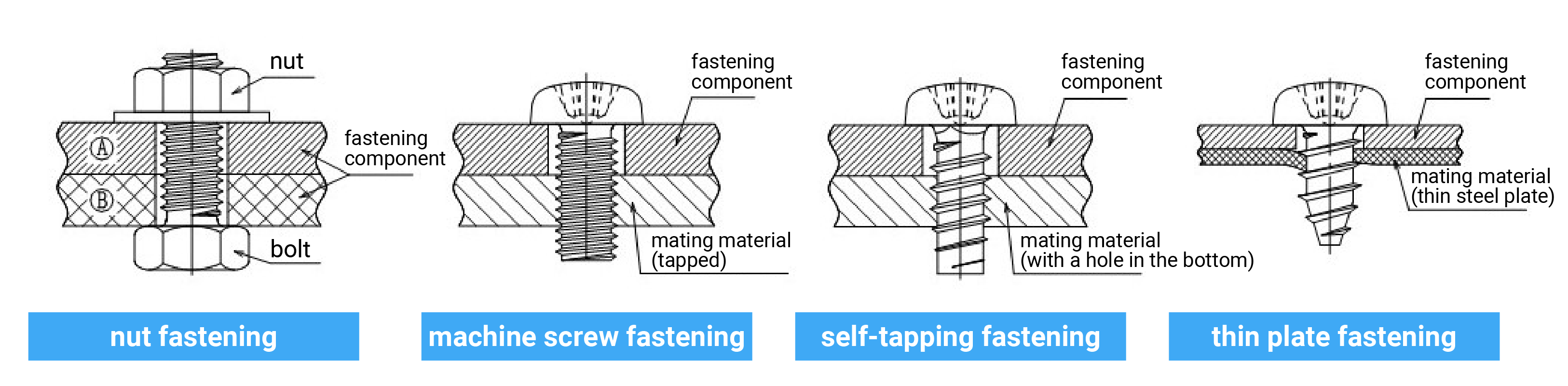

Example of screw fastening

The features of screw fastening are that the fastening force can be adjusted and that the parts can be disassembled if necessary. The fastening force is the force that squeezes the parts to be fastened together (the force that holds them down).

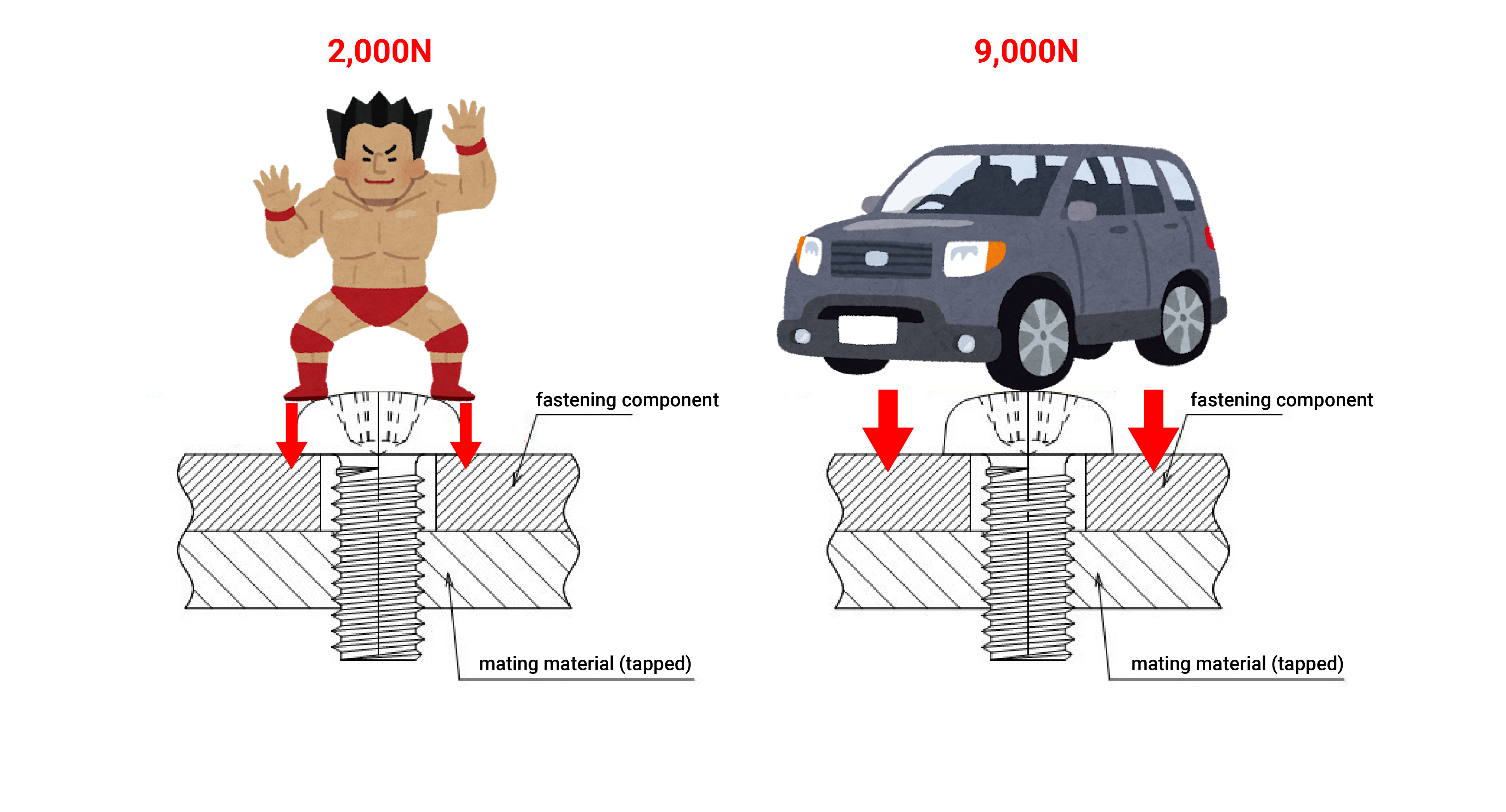

For example, in the case of an M4 machine screw, when the screw head seating surface is seated on the object to be fastened (0 N·m) to the recommended tightening torque (1.70 N·m), the tightening force can be adjusted from 0 N to approximately 2,000 N. A tightening force of approximately 2,000 N is the equivalent of a large prowrestler pressing down on the object.

In the case of an M8 small screw, the tightening force will be about 9,000 N when tightened with the recommended tightening torque (14.8 N-m). A tightening force of approximately 9,000 N is the equivalent of the weight of kei car pressing down on it.

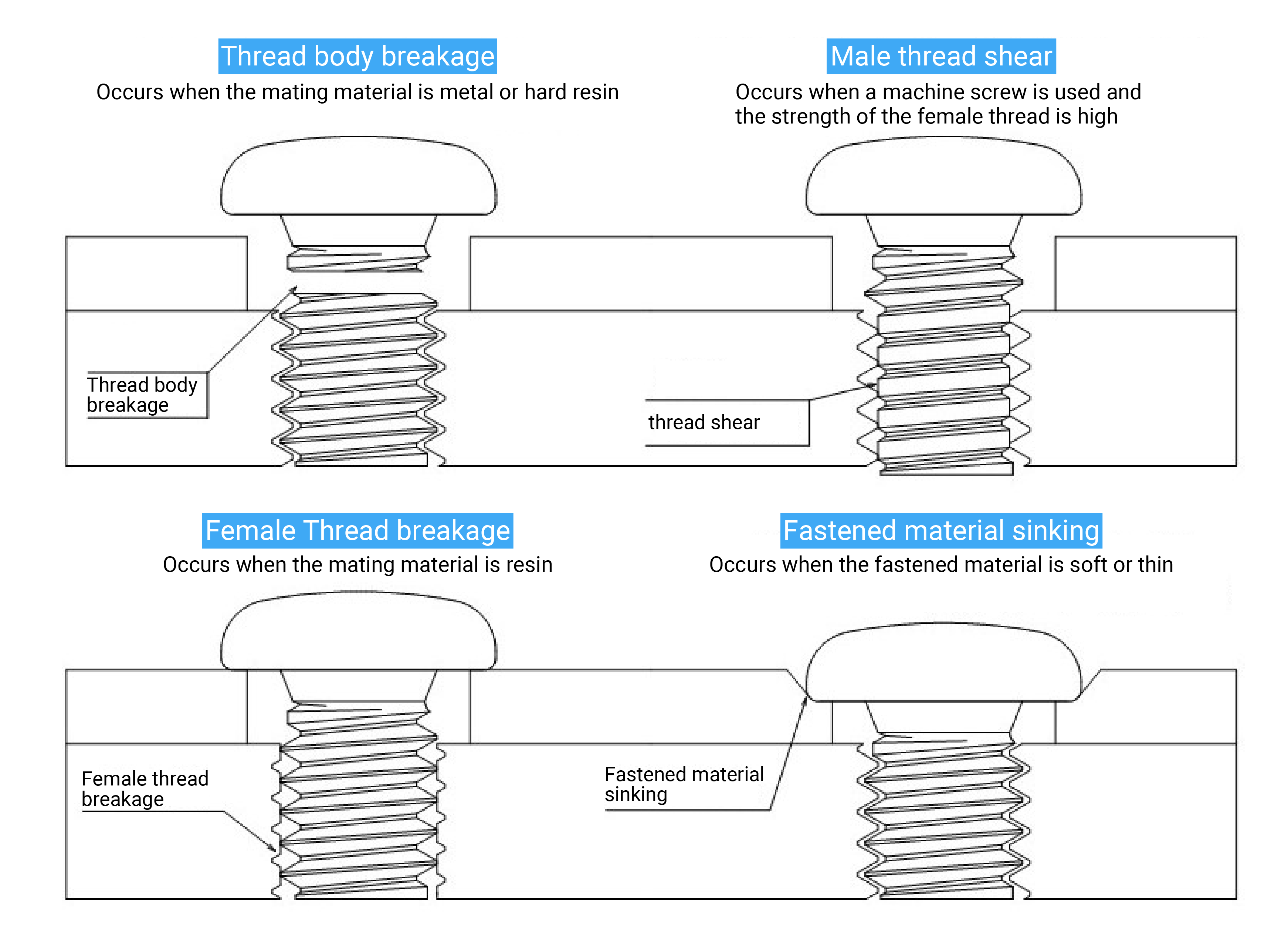

The fact that screw parts can be disassembled as necessary is one of their greatest advantages, but it also carries the risk of loosening. Therefore, when selecting and using screw parts, it is necessary to give sufficient consideration to preventing loosening. Generally, when fastening screws, there is a tendency to increase the fastening force (tighten more) in order to ensure that the fastening is secure and does not loosen. However, increasing the fastening force does not mean that the fastening will not loosen. If the screws are tightened too much, various problems can occur, such as the screws breaking, the mating material breaking, or the mating material being crushed.

Examples of problems caused by over-tightening

In particular, if the object being fastened is made of resin, over-tightening may cause creep (a phenomenon in which the deformation of the material increases over time due to the application of a constant external force for a long period of time: the shape does not return to its original state even after deformation).

There are various materials (metal, resin, aluminum, CFRP, etc.) that can be used for the material to be fastened, and the fastening conditions need to be changed depending on the strength and characteristics of the material. The same can be said for the material of the screw.