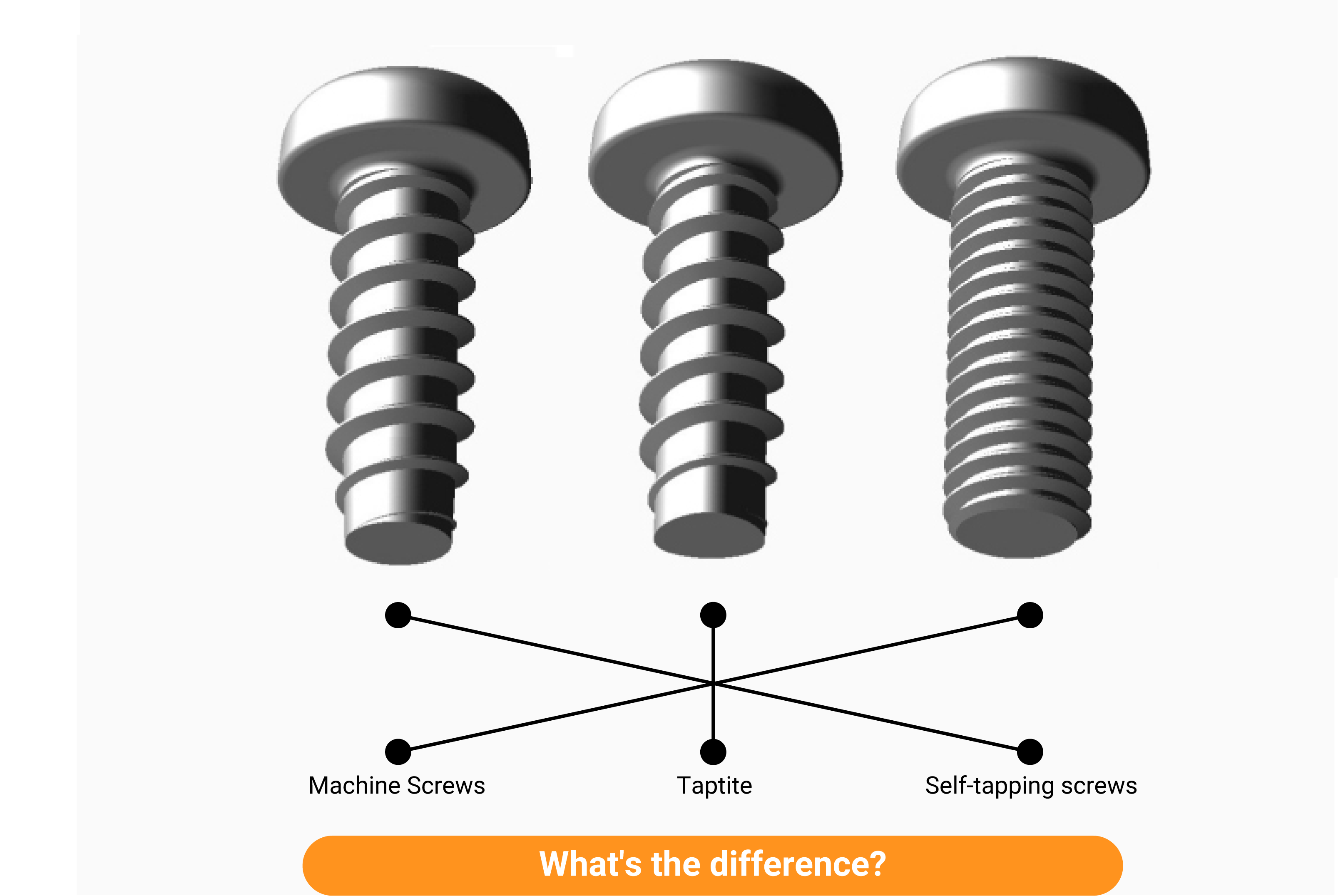

What's the difference between a small screw, a tapping screw, and a Taptite screw?

Machine Screws

There are male and female screws. The male side, “male screw”, has a screw thread (jagged) on the outside of the cylindrical or conical part of the screw, and the female side, “female screw”, has a screw thread on the inside. The basic screw fastening is achieved by combining a male screw and a female screw.

Generally speaking, machine screws (bolts) are male screws, and nuts are female screws.

|

|

| machine screws(male screw) | nut (female screw) |

Features

By using a nut (female thread) to fasten a machine screw, the screw can be screwed in with almost no resistance until the seating surface of the screw head comes into contact with the female thread. Because there is almost no resistance when screwing in, the fastening force can be transmitted to the fastening object without loss, so a higher axial force (force applied in the axial direction, fastening strength) can be obtained compared to tapping screws and Taptite. The advantage of small screws is that they can be fastened with high axial force (fastening strength), but if gaps form between the head seating surface and the mating material due to vibration, thermal shock, etc., and the axial force weakens, there is the disadvantage that the screw will easily loosen due to the lack of resistance in the screw section. As a method of increasing the resistance in the screw section and making it difficult to loosen, there are also cases where a coating agent with an adhesive or friction effect is applied to the screw section and used.

Self-tapping screws

Self-tapping screws are screws that can be screwed into a hole (pre-drilled hole) in a material that has not been threaded, while plastically forming the female thread with the screw's own thread. The process of screwing into a material while plastically forming the female thread is called self-tapping.

They are often used to reduce the cost of fastening and improve work efficiency, as they do not require female threading or insert nuts.

|

|

| Class 2 tapping screw |

Features

Because the screw threads themselves are used to plastically form the female threads in the unthreaded hole, resistance is applied from the start of the screw threading process. The resistance applied during screw threading means that the tightening force is reduced by the amount of resistance, and the axial force is lower than with a small screw.

Although the axial force is lower than that of a machine screw, even if the gap between the head seating surface and the mating material is created by vibration, thermal shock, etc., and the axial force is weakened, the resistance of the spring back of the mating material to the screw section due to plastic deformation prevents it from completely loosening and maintains a state where it is difficult to loosen.

Taptite screws

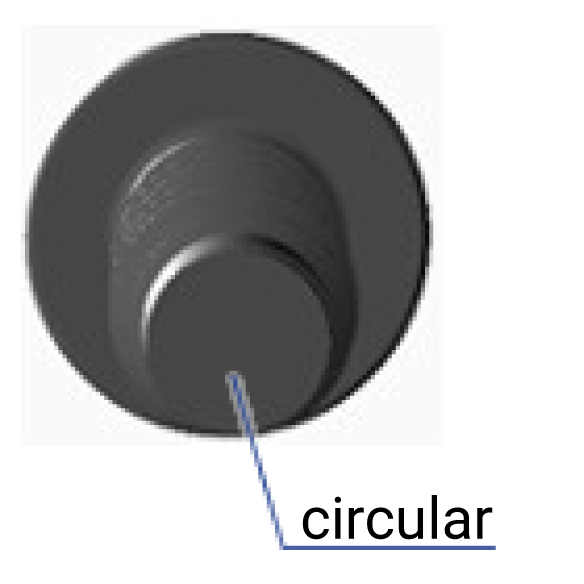

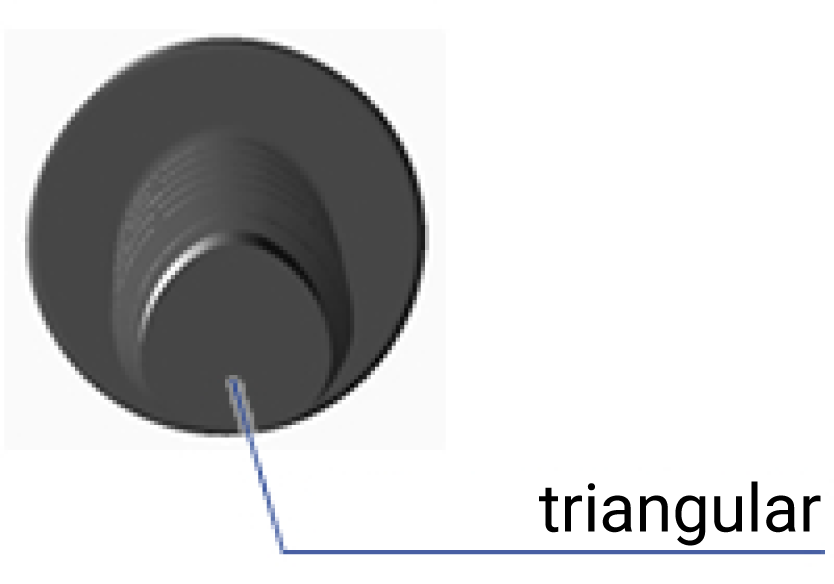

While the body of a normal tapping screw is circular, the body of a Taptite screw is triangular (like a rice ball). Like a tapping screw, it is screwed into a hole that has not been pre-threaded, using the screw's own thread to plastically form the female thread as it is screwed in. Taptite is superior to self-tapping screws in terms of workability and reliability, and is used in a wide range of industries. We have a lineup of various Taptite products, and we can provide the best screw and fastening solution for your material and application.

|

|

| B tite |

How the Tap-Tight works

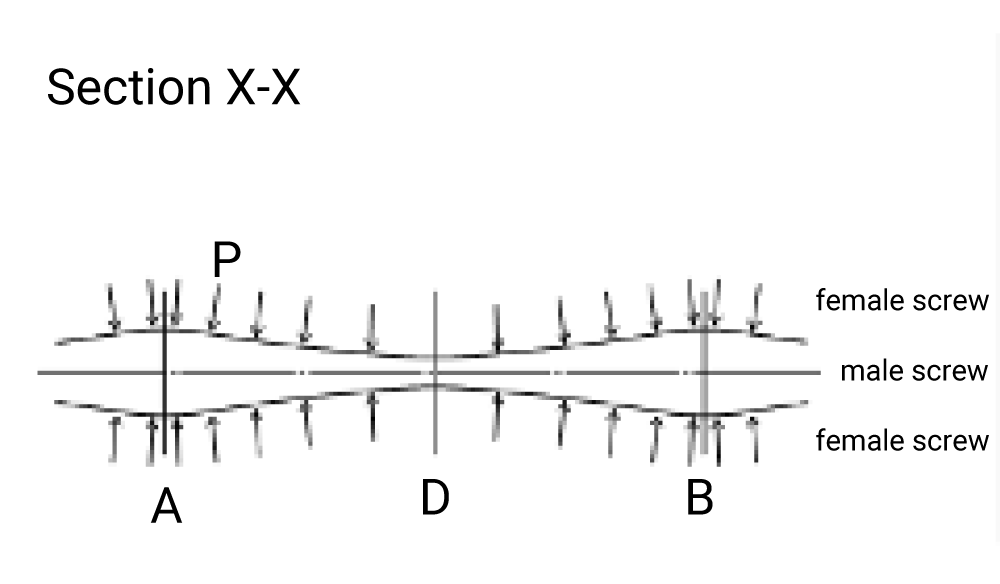

- The female screw is formed by pushing the mating material apart at three points (A, B and C). In this case, the male screw threads run away from the female screw threads at the edge of the triangle (D), so the internal stress of the mating material is relieved. Therefore, the contact resistance with the screw thread is reduced, and the screwing torque is lowered.

- Due to the springback of the female screw material, there is a state of stress concentration at points A, B and C, and at point D, the screw material contracts due to being pushed apart at points A, B and C, so it becomes a non-returning stop.

Features

As with tapping screws, resistance is felt from the start of screwing in, but because the body is triangular in shape, it is possible to screw in with less resistance than with tapping screws.

In addition, after screwing in, the spring back causes the other material (female screw material) to contract at the base of the triangular shape, which acts as resistance to loosening and provides a high loosening prevention effect. Therefore, even if a gap is created between the head seating surface and the other material due to vibration, thermal shock, etc., and the axial force is weakened, the screw section provides a high loosening prevention ability.

※Notes on setting the pilot hole for Taptite

- As the Taptite screw is screwed directly into the pilot hole, the pilot hole diameter setting is important. If the pilot hole diameter is too large, the screwability will improve, but there is a possibility that the pull-out strength will decrease and the screw will loosen easily.

- If the pilot hole diameter is too small, the screw torque will increase, which may interfere with workability.

- The appropriate pilot hole diameter should be set by considering the conditions of the screw type, engagement length, mating material, etc., as well as the desired results, such as loosening prevention and screwability.